Why Freeze-Dry

Raw feeding changed everything—but freeze-drying made it possible for everyone.

Dr. Bessent fed fresh, real food long before she ever freeze-dried a thing. She saw firsthand how whole ingredients supported her patients—how better nutrition made all the difference. But she also saw the barriers: frozen delivery, complicated prep, high cost, short shelf life.

Freeze-drying offered a solution. It helps preserve the integrity of fresh food—its nutrients, its aroma, its function—while creating a shelf-stable format that’s easy to store and serve, without spoilage or mess. It was a way to feed real food in a way that fit everyday life.

So she didn’t just adopt freeze-drying. She made it better. Dr. Bessent designed her own freeze-dryers and developed a carefully controlled preparation process so every batch meets our quality standards. The result is food that’s safe, convenient, and minimally processed.

It’s the reason our recipes exist today. Because real food works. Freeze-drying makes it work for everyone.

It All Starts with the Ingredients

We don’t believe in filler—and that starts with how we source. Every ingredient in our recipes is chosen for its nutritional value, not convenience. That means grass-fed, pasture-raised, wild-caught, or organic whenever possible.

Our meats are sourced from carefully selected suppliers that follow strict standards for handling, sanitation, and temperature control. We never use rendered ingredients or meats. Instead, we choose biologically appropriate cuts—like muscle meat, calcium-rich necks, and organ meats—that support your carnivore’s natural diet.

We also use real fruits, vegetables, and herbs, working only with vendors approved through our Supply Chain Qualification Program. This program evaluates suppliers based on food safety practices, handling protocols, and transportation conditions to ensure ingredient integrity from origin to arrival.

It’s not about checking boxes—it’s about building better food, from the very first step.

From Delivery to Prep

Once the ingredients are inspected and approved, we blend them into complete recipes and form them into nuggets. Then they’re frozen—ready for freeze-drying. Every batch is logged, every step documented, and every ingredient kept consistent from start to finish.

It’s not just production. It’s food craftsmanship, scaled for pets.

What Freeze-Drying Actually Does

Real ingredients. Minimal processing. Everyday ease.

Freeze-drying is a gentle way to preserve real food by removing moisture.

Instead of relying on heavy processing or freezing, it creates a lightweight, shelf-stable format that’s easy to store, serve, and travel with.

The result is food that maintains its natural aroma, texture, and nutrition—simply prepared and conveniently preserved for everyday life.

Real ingredients. Minimal processing. Everyday ease.

Third-Party Testing & Traceability

Every single batch goes through pathogen testing by a third-party lab.

No batch is released until it clears.

Once it gets the green light, retain samples and records of that batch are stored for 5 years post-manufacture. That gives us full backward and forward traceability—we can tell you exactly which ingredients went into your dog or cat’s bowl.

It’s not a marketing line. It’s a system built into how we work.

What Goes Into Every Bag

Every recipe starts with real food—and ends with a medley built for their species.

After freeze-drying, every medley is blended by hand, batch by batch.

-

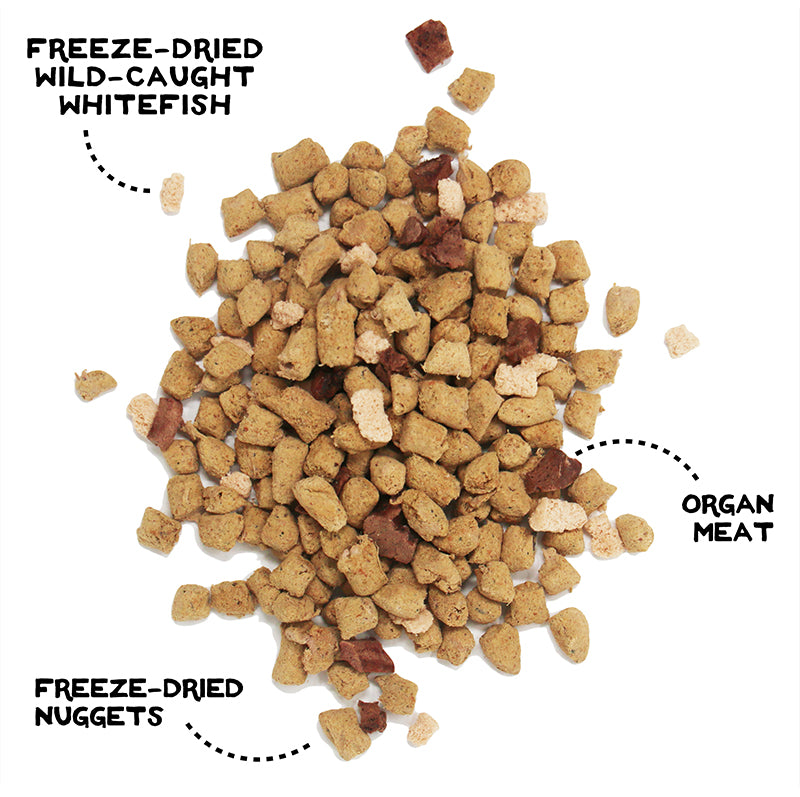

DOGS

For dogs, we create a nugget medley—freeze-dried pieces, air-dried nuggets, organ meats, fruits, and veggies—each one selected for taste, texture, and nutrition. The variety isn’t just for show. It’s built to match how scavenger carnivores actually eat.

- Freeze-dried nuggets

We combine all ingredients into one tasty morsel, and thanks to the freeze-drying process--they’re brimming with antioxidants, vitamins, and minerals.

- Dehydrated (AKA dry-roasted) nuggets

The same blend of meat-based proteins, fruits, veggies, seeds, legumes, and spices is dehydrated (or air-dried) and crumbled into little nuggets. This process makes for a nice, crunchy morsel of taste with that extra chomp dogs love.

- Freeze-dried organ meat

We order whole organs, like beef liver, and simply slice, dice, and pop it in the freeze-dryer. No processing, no altering. We prefer to keep it simple.

- Freeze-dried vegetables

We put a different combination of veggies in each of our recipes. The freeze-drying process retains all the natural vitamins and minerals in the vegetables and the taste, too!

- Freeze-dried fruits

Whole, freeze-dried fruits, like apples or cranberries, can be seen sprinkled in with the freeze-dried and dry-roasted nuggets. Bursting with vitamins and minerals, these additional ingredients round out a well-balanced diet.

-

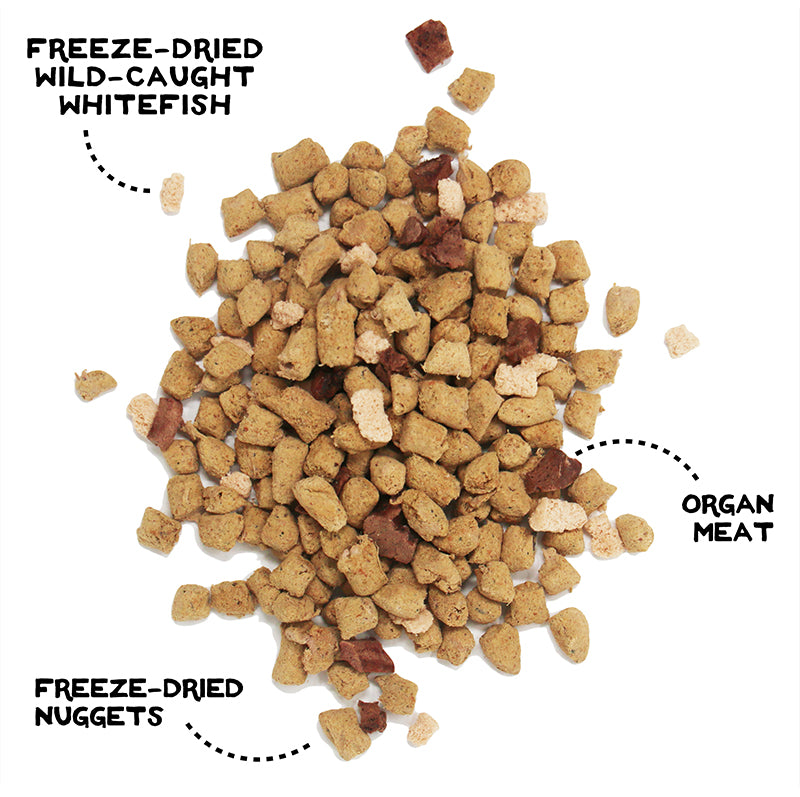

CATS

For cats, we simplify. Every recipe includes freeze-dried nuggets, sliced organ meats, and whole proteins—because obligate carnivores thrive on meat-first simplicity.

- Freeze-dried nuggets

We combine all ingredients into one tasty morsel, and thanks to that freeze-drying process, they’re brimming with antioxidants, vitamins, and minerals.

- Freeze-dried meat

Whole proteins like wild-caught whitefish are sliced and diced and head straight to the freeze-dryer, creating rather aromatic morsels to send carnivores reeling.

- Freeze-dried organ meat

Whole organs, like chicken liver is simply sliced, diced, and popped in the freeze-dryer. No processing, no altering. We prefer to keep it simple.

Small Batches, Big Difference

500 pounds at a time. Not 50,000.

-

Most pet food is mass-produced—giant mixers, mega runs, and limited oversight. We chose a different path.

Our batches range from 250–500 pounds—small enough for our team to stay hands-on. Every blend is tracked, measured, and adjusted as needed. Every production record is tied to a lot code we retain for 5 years.

Small batches let us:

- Keep ingredients fresh and traceable

- Respond to seasonal or supply shifts without compromising

- Maintain better control of texture, nutrient balance, and safety testing

- Package with purpose—instead of bulk bins with air exposure

Each recipe is hand-blended at the final stage—balancing dehydrated, freeze-dried, and organ components according to strict formulas. It’s the kind of precision you can expect nowhere but The Simple Food Project.

- Keep ingredients fresh and traceable

-

Typical Production:

50,000 lbs per run

or an entire semi-truck packed to the roof with processed kibble

-

Our Batches:

250–500 lbs per batch

ours? You can carry it on a pallet.

Inside Our Vet Owned & Operated Facilities

No co-packers. No shortcuts. Built by Dr. B, still run by her.

Dr. Bessent built this facility when she realized no one else was doing it the way she believed it should be done.

We don’t license our recipes. We don’t ship ingredients off to third parties. From blending to freeze-drying to final packaging—it’s all done here in Wisconsin.

- 2 GMP-certified facilities

- Registered with the FDA

- Operate under FSMA and HAACP guidelines

- 2 PCQI-trained team members monitor production daily

We built this infrastructure to keep our standards high, our sourcing transparent, and our safety measures rock-solid.

Why We Pack in Small Bags

Because air is the enemy of nutrition

Here’s something you might not think about when it comes to food quality: oxygen.

Even with resealable packaging, once you open a bag, air starts to work against the nutrients inside. That’s why we package everything in 24 oz bags—even if you order in bulk.

It's the same logic as keeping your broccoli crisp. Day 1 broccoli? Great. Day 14? Not so much.

Smaller packaging =

- Limited oxygen exposure

- Flavors, textures, and nutrients are more stable

- Better scoops, all the way through

This is one of those small choices that makes a big difference.

The Process Matters. But Ingredients Matter More.

Freeze-drying can be a game changer—but only if you start with food that’s worth preserving. We’ve made it our mission to craft that food from the ground up, no matter the batch size.

Because it’s not just about skipping the freezer. It’s about choosing better—better sourcing, better safety, and better nutrition, bowl after bowl.

With freeze-drying, pet parents don’t have to choose between raw food and convenience. You get all the benefits of whole food—real taste, real nutrients, real ingredients—without sacrificing shelf life or sanity.